News & Blog

News & Blog

Meet Dilan

In honour of Engineering Week 2024 and Girl Day, we're excited to introduce you to Dilan, our newest team member.

Filter articles by category

-

Read More

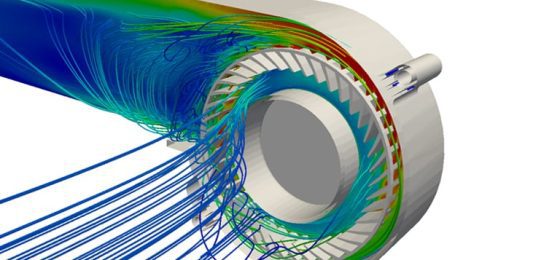

Read MoreHow do You Control the Pressure of a Centrifugal Fan?

Pressure control in centrifugal fans and blowers is crucial for...

-

Read More

Read MoreWhat Are Common Applications For Industrial Fans?

Even though most people are aware of their existence, industrial...

-

Read More

Read MoreWhat Are The Advantages Of A Tangential Fan?

Tangential fans, also known as cross-flow fans, offer unique advantages...

-

Read More

Read MoreTestimonial: Enertech Limited

I’ve always found the service provided by the team at...